Optimizing Factory Performance

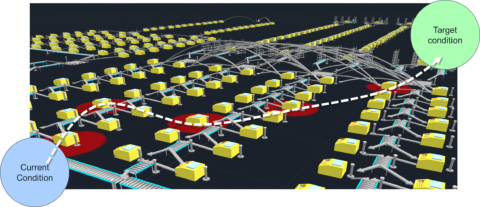

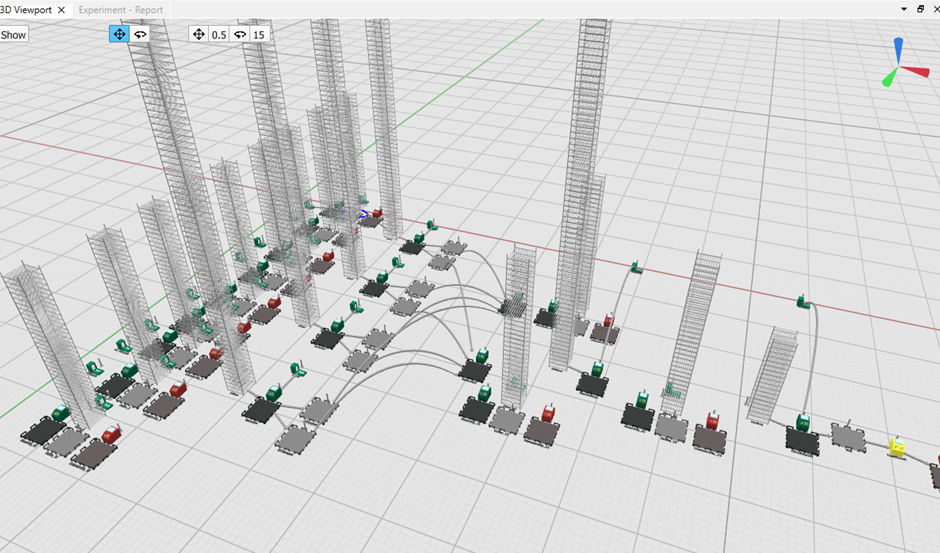

A discrete parts manufacturer in the automotive industry faced difficulties in managing a multi-step production system with parallel machining, assembly, and final assembly flows. Variations in shift schedules and process constraints made it challenging to maintain a smooth and efficient operation across the entire factory.

Challenge

A production facility struggled with high buffer levels, long lead times, and inefficiencies in product sequencing. These issues led to:

- Increased production costs due to excessive material storage.

- Delays in production flow impacting delivery timelines.

- Difficulty in balancing shift work and workforce allocation.

Solution

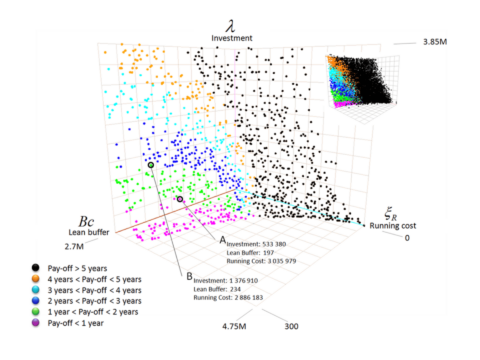

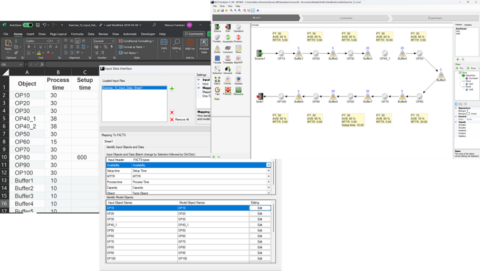

With FACTS Analyzer*, the company could:

- Reduce buffer and store levels while ensuring uninterrupted production.

- Analyze and optimize product sequences to minimize wait times.

- Evaluate different shift configurations for increased efficiency.

Results

- 25% reduction in buffer/store levels.

- Shorter lead times, improving overall factory performance.

- Optimized shift patterns leading to improved workforce utilization.

Conclusion

With data-driven insights and simulation-based optimizations, the company achieved higher productivity, reduced operational costs, and improved production flow.

*FACTS Analyzer was the previous generation of inFACTS Studio, built on a 2D environment.