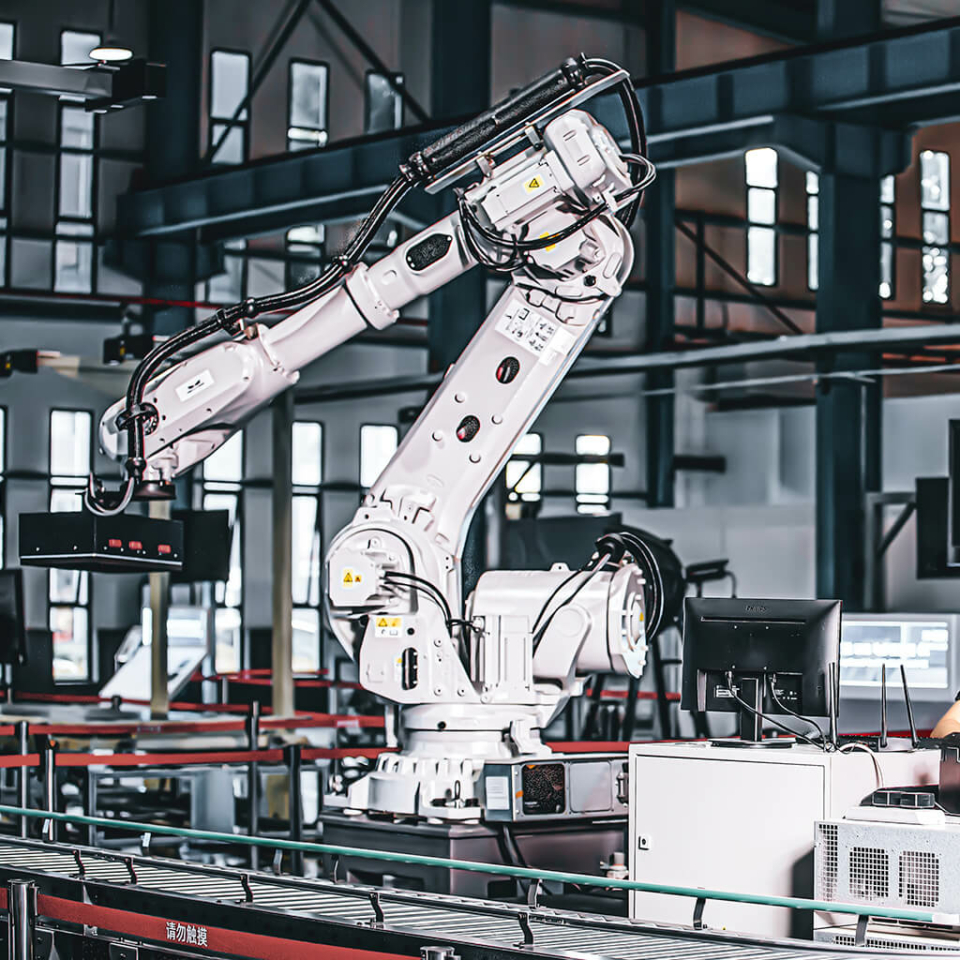

Evoma for Automotive

Evoma lets automotive manufacturers and suppliers optimize their production flow with minimum investment/improvement cost and hence elevate their profitability.

Bottlenecks analysis

Where and what are the minimum changes (lowest cost) in order to improve the overall capacity of the line? Where to improve or to reduce buffers/storages to cut overall manufacturing lead-time without sacrificing the capacity. Our unique SCORE method will help you to answer these questions automatically.

Multi-objective optimization

MOO can effectively answer questions like: what is the minimum investment/buffer capacities/resources in order to attain the required capacity? What is the minimum stock to attain the customer service level target?

Rapid modelling

Designed with the principle of rapid modeling using smart manufacturing modeling objects. While its core goal remains to enable users to build simulation models without requiring programming skills, it now also supports advanced customization through C++ for those who wish to extend functionality further.

Originating from the idea that Discrete-Event Simulation (DES) could be frontloaded to support early stages of automotive production system design, FACTS Analyzer was developed as a Factory Conceptual design Tool using Simulation (FACTS). Its main purpose was to empower manufacturing professionals—especially during the conceptual phase—to use simulation without requiring programming skills.

FACTS Analyzer has been successfully applied across several Swedish automotive companies, covering production of cars, trucks, and buses. Many professionals—from technicians to managers—have used it independently, without support from simulation experts. A notable success is how production engineers have used FACTS Analyzer for continuous improvement, running Simulation-Based Optimization (SBO) weekly to identify bottlenecks and determine optimal actions to boost production capacity.

Enter inFACTS Studio – Smarter Simulation for the Future

As the next-generation successor to FACTS Analyzer, inFACTS Studio expands on its core principles with powerful new capabilities. It combines intuitive drag-and-drop modeling with advanced features such as C++ customization, multi-objective optimization, and AI-powered analytics—making it suitable for both non-programmers and advanced users.

Designed for manufacturing, logistics, and supply chain applications, inFACTS Studio helps businesses simulate, optimize, and gain actionable insights to support smarter, more sustainable decisions.

🔗 Read more about inFACTS Studio

Why facts analyzer is special?

- Rapid modeling with smart objects

- Data interface for model generation and model updated, including spreadsheet data exchange.

- C++ programming interface for custom logic.

- Accurate and fast models.

- Cloud-enabled parallel simulations and integrated multi-objective optimization.

- Data mining and advanced data analytics.

- Automatic bottleneck identification and prescriptive analytics with the unique SCORE method.

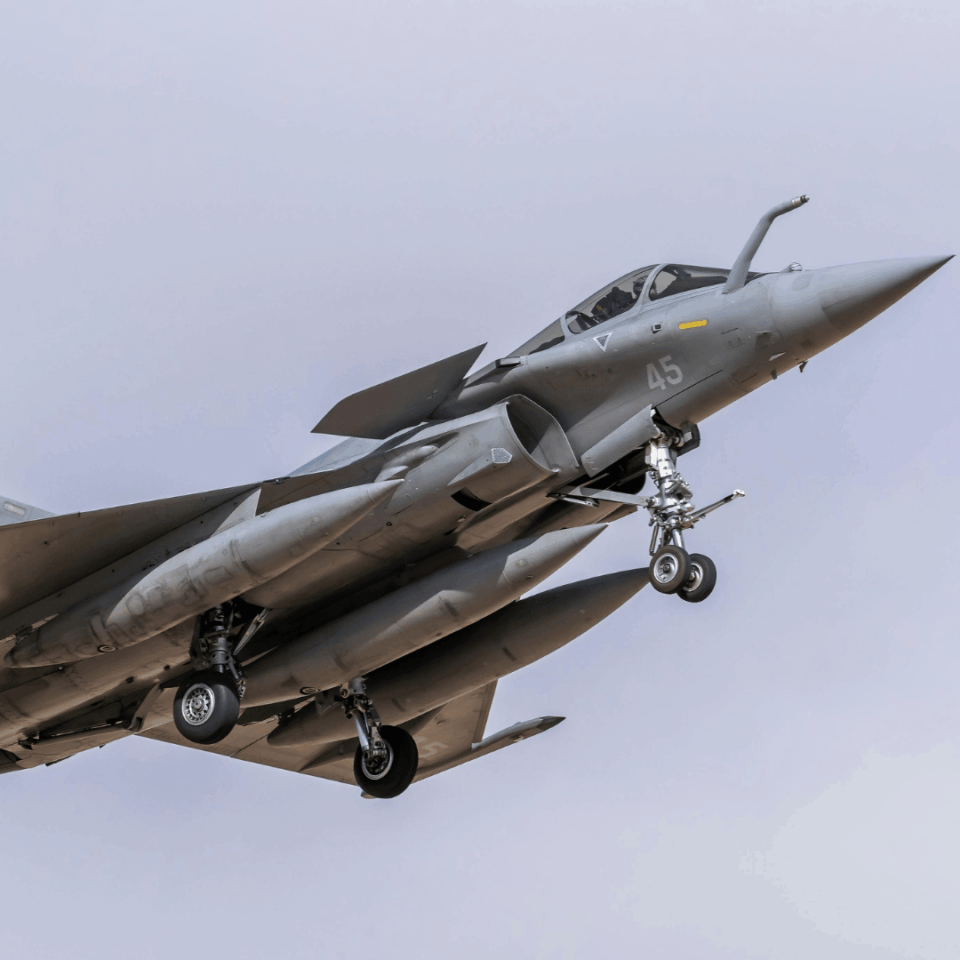

Other industries suited for our software

How can we help you?

If you’re a business with a large license volume or unique business model, reach out to discuss alternative pricing options.

Our teams will review your current statements and can help design a customized pricing package.