Bottleneck Analysis

inFACTS Studio supports several methods for identifying bottlenecks in a system, including those based on resource utilization statistics, buffer utilization statistics, shifting bottleneck detection, and our own invention for Simulation-based COnstraint REmoval (SCORE).

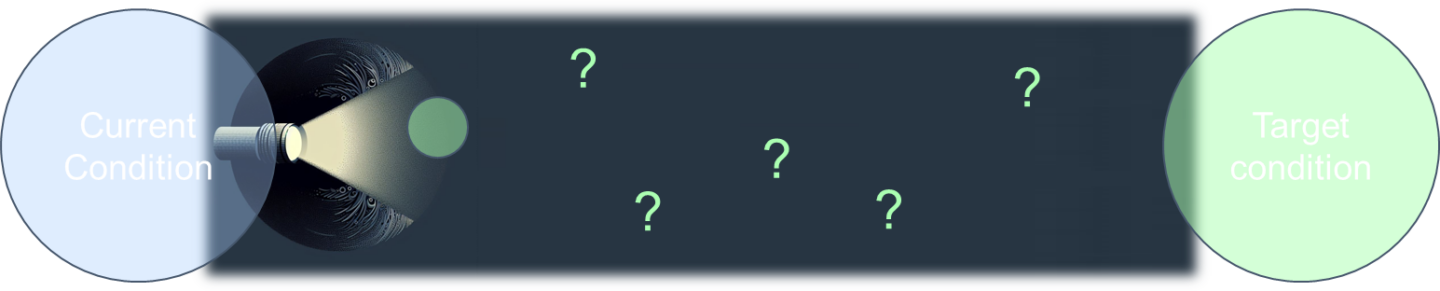

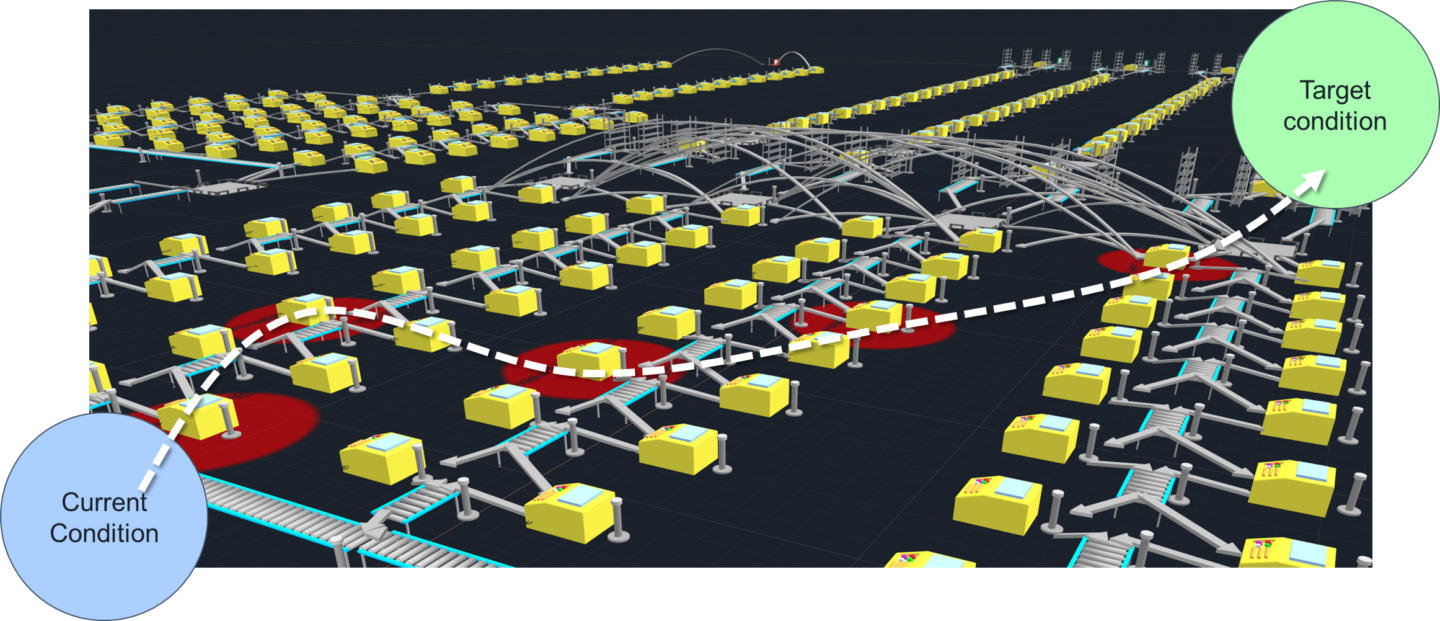

Many production managers and engineers often lack a clear strategy for optimizing entire production lines, particularly when faced with the need to increase production capacity. In most situations, identifying the bottleneck(s) is only the first step toward reaching the goal of improving a system. Traditional methods like trial and error, as suggested by Lean practices, fall short in predicting the effects of changes. Similarly, AI and Big Data without simulation only learn from historical data, limiting their predictive capabilities. Hence, quite often it is a step-wise process that may look like this:

Evoma tackles this challenge by offering a novel, award-winning* bottleneck analysis method named SCORE (Simulation-based Constraint Removal), which transforms bottleneck analysis into a multi-objective optimization problem. In a single optimization run, SCORE explores various combinations of improvement actions on the processes to achieve the maximized throughput of a production system. The method considers factors like processing times, availabilities, and repair times as potential causes for bottlenecks, making it adaptable to a broader range of bottleneck causes such as quality deficiencies, resource shortages, and buffer issues. This innovative approach not only predicts the effects of changes in production lines but also identifies optimal improvement changes, enabling production managers to significantly enhance productivity.

Explore our upcoming whitepaper, “Where is the Bottleneck? It depends!”, for a deeper understanding of SCORE. Stay tuned for its release!

*Volvo Car Technology Award

How can we help you?

If you’re a business with a large license volume or unique business model, reach out to discuss alternative pricing options.

Our teams will review your current statements and can help design a customized pricing package.