Bottleneck and System Performance Analysis

Hidden constraints can silently limit system efficiency. Bottleneck identification and analysis are critical for improving throughput, reducing delays, and optimizing production flow.

There are several methods used to identify bottlenecks in production systems:

- Buffer Analysis: Accumulation of WIP before a machine often signals downstream constraints.

- Blocked → Waiting Transitions: If one machine is often blocked and the next is frequently waiting, this relationship reveals a constraint in between.

- Utilization-Based Detection: As per Factory Physics (Hopp & Spearman, 2011), the station with the highest utilization (arrival rate ÷ capacity) is the bottleneck.

- Operation Time / Machine Utilization: Average time a machine is busy over the total available time can highlight bottlenecks.

While these methods provide valuable insights, they often rely on long-term averages, static conditions, or difficult-to-capture real-world data.

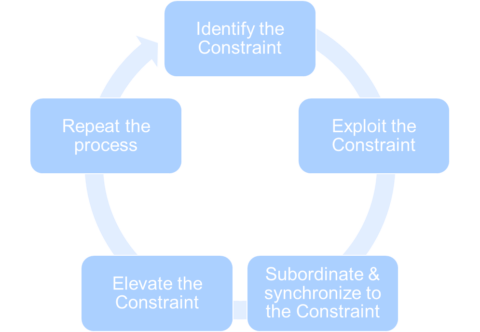

Shifting Bottleneck Detection – A Dynamic Approach

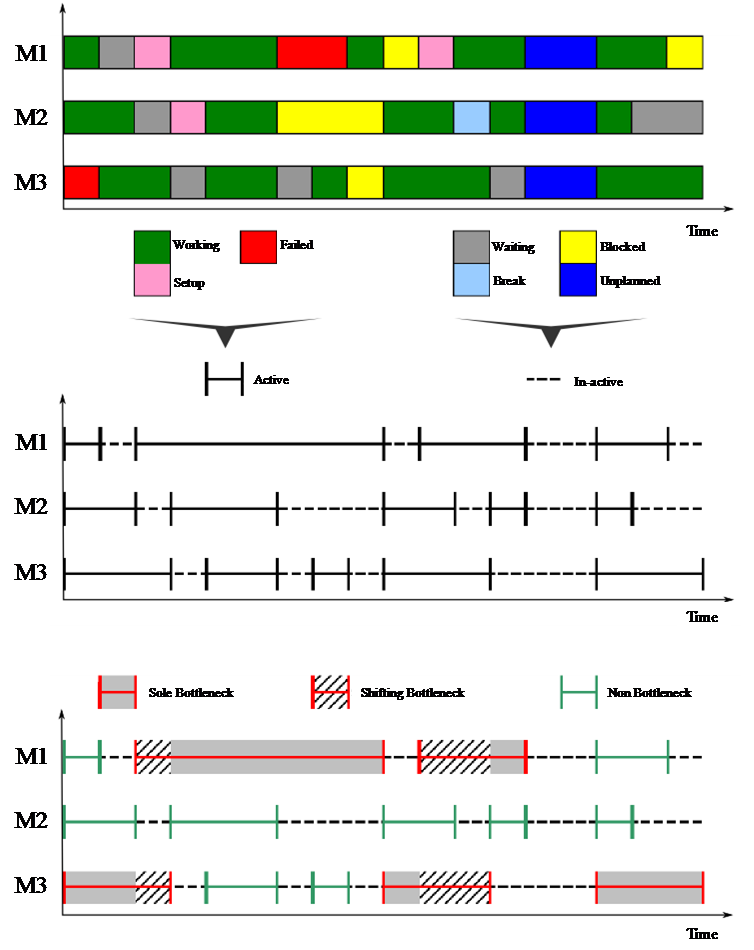

Shifting Bottleneck Detection, introduced by Roser, Nakano, and Tanaka (2002) at Toyota Software Laboratory, offers a more dynamic and granular method:

- It identifies the momentary bottleneck as the machine with the longest active period (working, failed, setup).

- Bottlenecks can shift over time due to dynamic conditions like machine failures, changeovers, or scheduling.

- Overlapping bottlenecks are tracked and visualized — crucial for understanding complex, real-world flow behavior.

This method allows for timeline-based bottleneck tracking, as visualized in the image, clearly showing how bottlenecks evolve and interact over time.

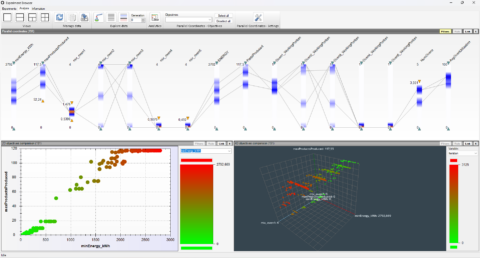

Simulation Support with inFACTS Studio

inFACTS Studio has Shifting Bottleneck Detection built-in, providing:

- Automatic categorization of machine states (e.g. working, setup, blocked, unplanned).

- Visualization for detailed analysis of bottleneck behavior, i.e. sole and shifting bottleneck periods.

Challenges

- Hidden Constraints: What truly limits system performance at different times?

- Throughput Limitations: How can output be increased without capital investment?

- Strategic Focus: Where will improvement efforts deliver the highest return?

How Simulation Helps

- Identifies bottlenecks and evaluates their impact on the system.

- Simulates alternative solutions, such as improvements or new investments.

- Provides data-driven insights for optimizing system performance.

Expected Results

- Higher throughput without unnecessary capital investment.

- Reduced cycle times by eliminating bottlenecks.

- Improved overall equipment effectiveness (OEE).