Buffer Optimization and Reduction

Optimizing Work-In-Progress (WIP) levels ensures smooth production without excess inventory. Companies must balance cost, lead time, and efficiency to prevent disruptions. However, not all buffers are created equal — distinguishing between different buffer types is key to sustainable optimization.

In manufacturing systems, buffers serve different roles:

- Necessary Buffers such as Standard Work In Process (SWIP) are minimal and intentional levels of WIP designed to ensure a continuous flow in line with takt time. These are crucial for absorbing small fluctuations and keeping processes decoupled just enough to avoid bottlenecks.

- Transit Buffers represent materials in movement between process steps or facilities. While they may not be visible on the shop floor, they impact flow and lead time significantly.

- Non-Necessary Buffers are typically unplanned or excessive WIP that accumulates due to poor flow design, variability, or scheduling inefficiencies. These contribute to waste (muda), increase lead times, and tie up capital and floor space.

While some buffers may be justified to maximize equipment utilization, exceeding levels such as SWIP often yields diminishing returns — increasing cost and complexity without proportional gains in throughput or stability.

Challenges

- Excessive Buffers: How can inventory levels be reduced without increasing disruptions?

- Insufficient Buffers: How can WIP be optimized to prevent bottlenecks?

- Cost vs. Efficiency Trade-Offs: When does added inventory stop contributing to performance?

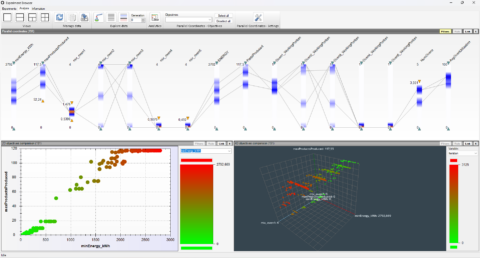

How Simulation Helps

- Distinguishes between essential and non-essential buffers based on flow requirements.

- Determines optimal buffer sizes using real production dynamics and variability.

- Simulates trade-offs between inventory cost, throughput, and system stability.

- Identifies opportunities to minimize WIP without jeopardizing flow or lead time.

Expected Results

- Clearer buffer strategy, differentiating required vs. excessive inventory.

- Lower inventory costs and reduced capital tied up.

- Optimized use of space — fewer square meters occupied unnecessarily.

- Balanced WIP levels that protect against disruptions without overstocking.

- Shorter lead times and more predictable, stable production.