Capacity Planning – Ensuring Scalable Production

Managing production capacity requires balancing resources to meet market demands while avoiding over- or under-utilization. Companies need strategies for effective workforce distribution and machine allocation.

Challenges

- Fluctuating demand: How to balance capacity with market variations without over- or under-utilizing resources?

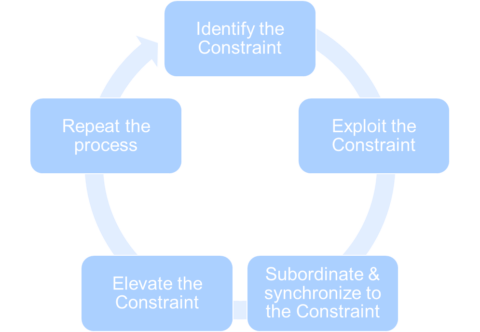

- Bottlenecks & constraints: Where are the system’s capacity limitations, and how do they impact throughput?

- Investment decisions: When is it necessary to expand production capacity vs. optimizing existing resources?

- Workforce & machine allocation: How to distribute resources effectively across multiple production lines?

- Scalability: How will the system handle future growth and unexpected increase in demand?

How Simulation Helps

inFACTS Studio enables companies to:

- Model different production volume scenarios to identify capacity constraints before they occur.

- Simulate alternative capacity strategies such as overtime, additional shifts, or machine investments.

- Optimize workforce and machine allocation to ensure efficient resource distribution.

- Evaluate system scalability to support long-term business growth.

Expected Results

- More accurate capacity planning with data-driven decision-making.

- Reduced risk of over- or under-utilization by testing strategies in a virtual environment.

- Optimized production investments by identifying when expansion is truly necessary.

With inFACTS Studio, businesses can simulate and refine capacity strategies to maintain production efficiency, meet demand fluctuations, and ensure long-term scalability.