Conceptual Development & Production Concepts

Companies face difficulties in evaluating and comparing different manufacturing system concepts before implementation. Choosing the right strategy is crucial for production efficiency, cost-effectiveness, and long-term scalability.

Challenges

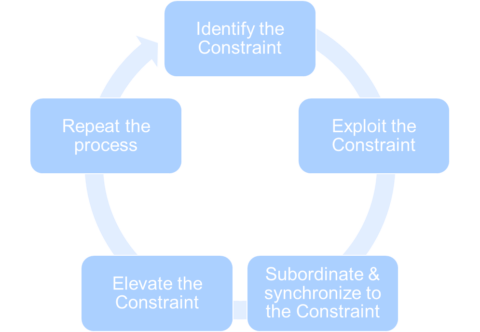

- How do my KPIs change with a push strategy, pull strategy, or CONWIP (Constant Work in Progress) strategy?

- What is the ideal production layout for a specific product segment?

- How do different automation levels impact cycle times, operator workload, and system bottlenecks?

- What is the trade-off between batch sizes, setup times, and resource utilization?

How Simulation Helps

Discrete Event Simulation (DES) and optimization provide a data-driven approach to evaluate and compare production concepts before investing in physical implementation. inFACTS Studio allows companies to test various production scenarios in a risk-free environment, helping decision-makers visualize how different strategies impact throughput, resource utilization, costs, and lead times.

- Model various production concepts using inFACTS Studio to replicate push, pull, and CONWIP control strategies in a simulated environment.

- Compare layout configurations, such as job shop, cellular layout and flow layout to evaluate system and resource efficiency.

- Analyze equipment utilization, material flow, and takt time under different production strategies.

- Apply multi-objective optimization to determine the optimal balance between production speed, energy consumption, and buffer levels.

- Visualize the impact of different scheduling strategies, automation levels, and resource constraints.

Expected Results

- Optimized production system design based on data-driven insights before implementation.

- Reduced lead times and buffer sizes by selecting the best production control strategy.

- Improved flexibility and scalability by testing alternative manufacturing configurations.

- Better decision support for capital investments, minimizing risks before purchasing new equipment.

- Sustainability improvements by identifying energy-efficient production setups.