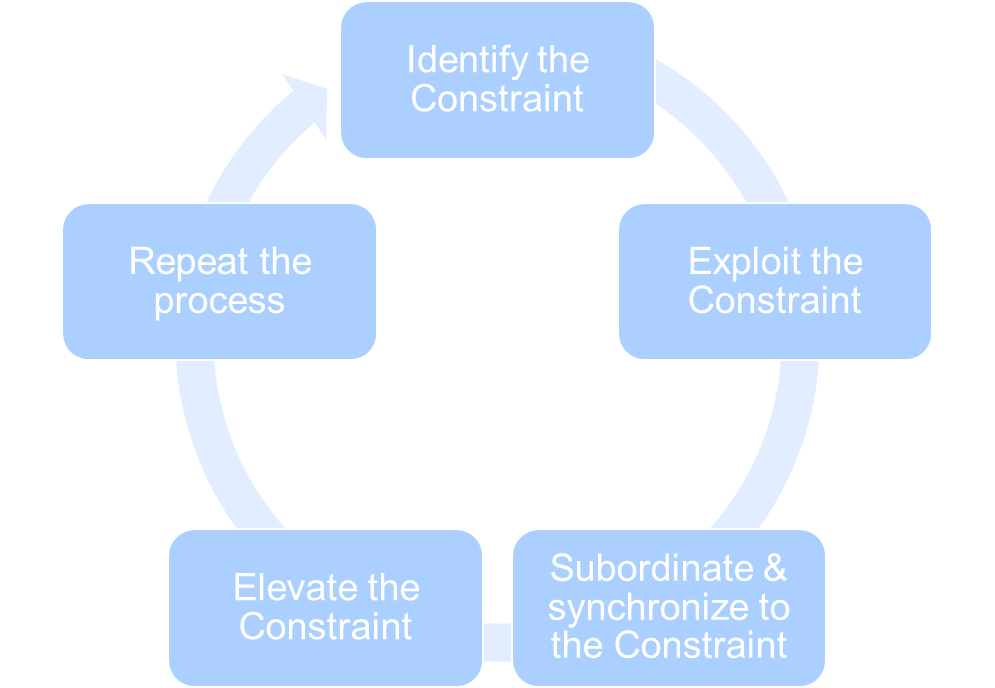

Constraint Identification & Optimization (Theory of Constraints)

Pinpointing and resolving primary constraints in production ensures optimal system performance. Companies need structured, data-driven strategies to eliminate bottlenecks and enhance efficiency.

Challenges

- Bottlenecks reducing throughput – How can we pinpoint the primary constraint limiting overall production efficiency?

- Resource inefficiencies – How should supporting resources be synchronized to optimize constraint performance?

- Capacity limitations – When does investment in additional resources become necessary for system improvement?

- Continuous system monitoring – How can we ensure new constraints are identified as production changes over time?

How Simulation Helps

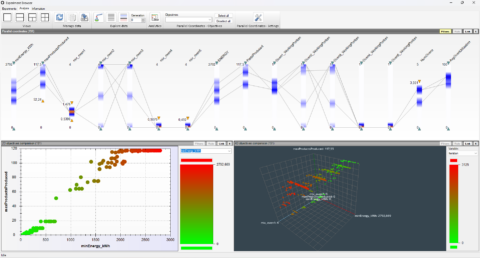

Discrete Event Simulation (DES) and optimization provide a data-driven approach to evaluate and compare production concepts before investing in physical implementation. inFACTS Studio allows companies to test various production scenarios in a risk-free environment, helping decision-makers visualize how different strategies impact throughput, resource utilization, costs, and lead times. Key questions include:

- Identify the System’s Constraint(s): Use data analytics and simulation to detect process bottlenecks and system limitations.

- Optimize the Constraint: Run what-if analyses to maximize the utilization of the existing constraint under current conditions.

- Align Other Resources: Use multi-objective optimization to fine-tune supporting processes, ensuring synchronization around the constraint.

- Evaluate Capacity Expansion: Test different investment strategies (e.g., adding machines, modifying shifts) to determine the best approach for constraint elevation.

- Continuous Improvement: Implement real-time performance tracking and scenario testing to detect new constraints as the system evolves.

Expected Results

- Data-driven constraint management – Fact-based identification of system bottlenecks.

- Optimized resource allocation – Supporting resources aligned to maximize constraint efficiency.

- Smart investment decisions – Validation of expansion strategies before committing to capital expenditures.

- Continuous system performance improvement – Adaptive constraint analysis ensuring ongoing optimization.

With inFACTS Studio, companies can apply the Theory of Constraints (ToC) methodology in a risk-free environment using simulation, optimization, and advanced analytics to identify, manage, and elevate constraints—leading to higher efficiency, reduced costs, and improved system performance.