Energy Optimization – Reducing Consumption While Maintaining Throughput

Balancing energy efficiency with production output helps lower operational costs. Companies need simulation-based insights to minimize consumption without affecting performance.

Challenges

- High energy costs: How can production processes be optimized to minimize energy consumption?

- Sustainability goals: How can companies reduce their carbon footprint without sacrificing performance?

- Process efficiency: How does machine scheduling and load balancing impact energy use?

- Trade-offs: How to balance energy savings with production throughput and lead times?

How Simulation Helps

inFACTS Studio enables companies to:

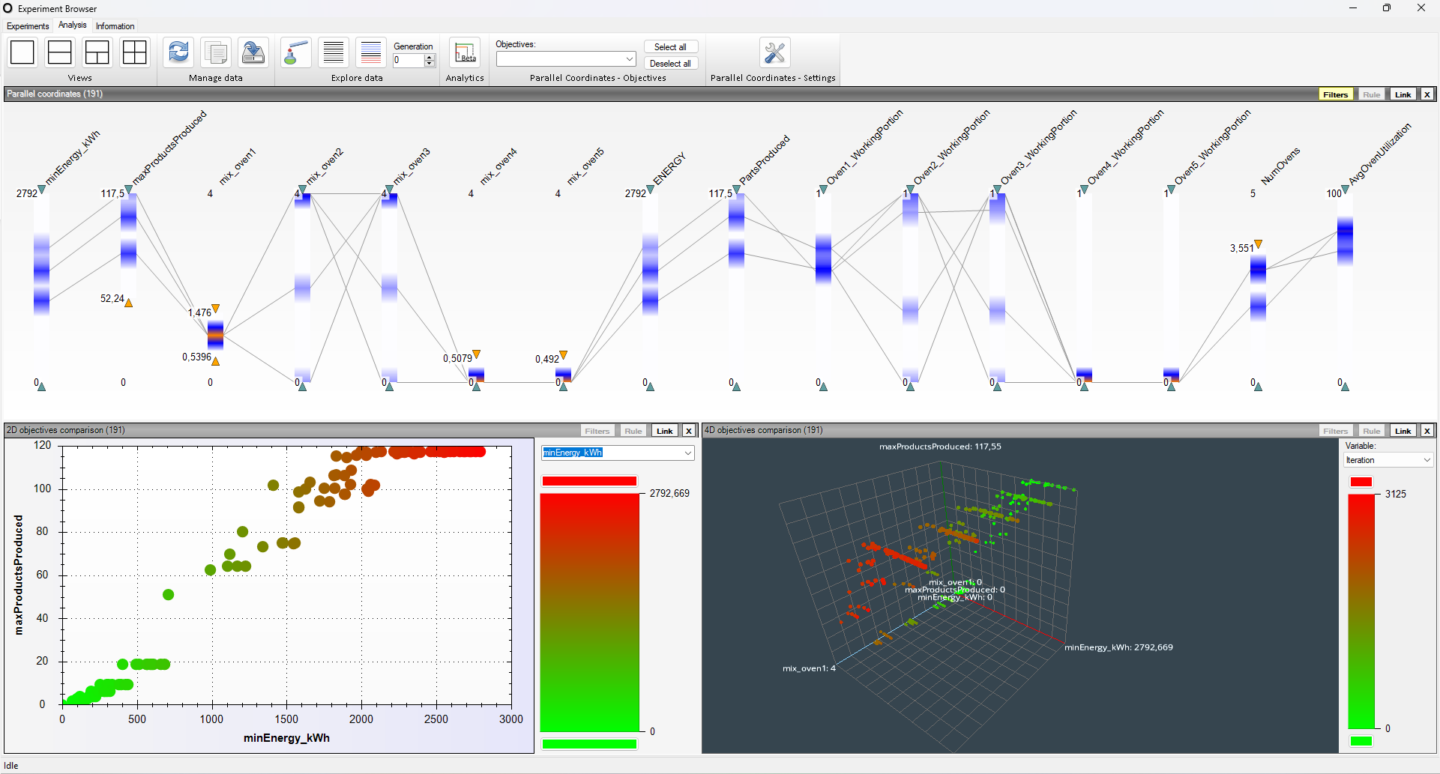

- Identify energy-saving strategies by simulating different production schedules and machine operations.

- Analyze equipment energy consumption under varying workloads and production rates.

- Optimize machine utilization to reduce idle time and unnecessary power usage.

- Balance energy efficiency with throughput by finding the optimal operating conditions.

Expected Results

- Reduction in energy consumption without compromising output.

- Optimized machine usage leading to lower operational costs.

- Improved sustainability metrics helping companies meet energy and environmental goals.

With inFACTS Studio, manufacturers can make data-driven decisions to minimize energy consumption while ensuring production targets are met.

Note: The sustainability functionality (including energy modelling) is currently in a beta stage and soon to be integrated into the software. Contact us if you want to know more!