Equipment Selection – Balancing Cost, Performance, and Future Needs

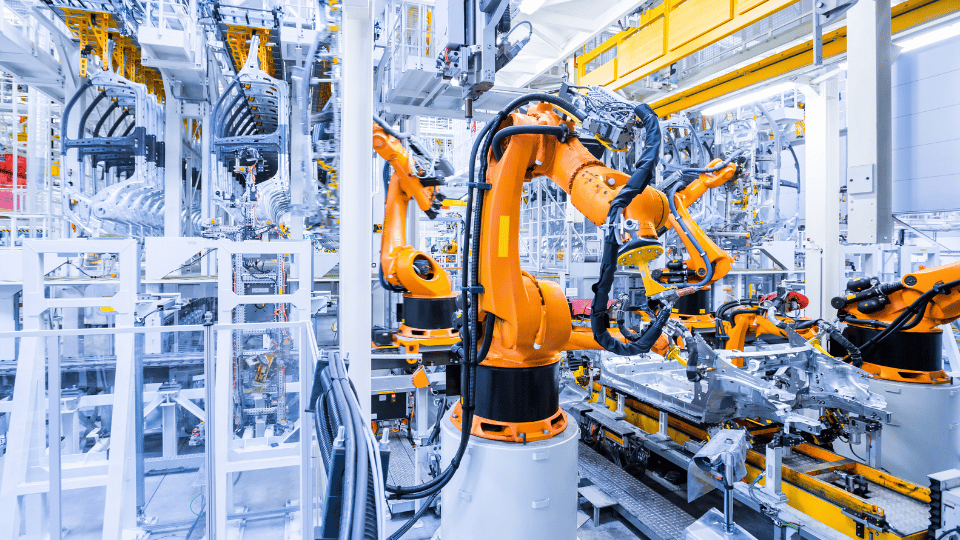

Choosing the right equipment requires balancing investment cost, scalability, and production efficiency. Companies must evaluate machine performance, process compatibility, and long-term flexibility to make data-driven decisions.

Challenges

- Cost vs. performance: How to select machines that balance investment cost and productivity?

- Scalability: Will the selected equipment support future production expansion or changes?

- Process compatibility: How well does the equipment integrate into existing workflows?

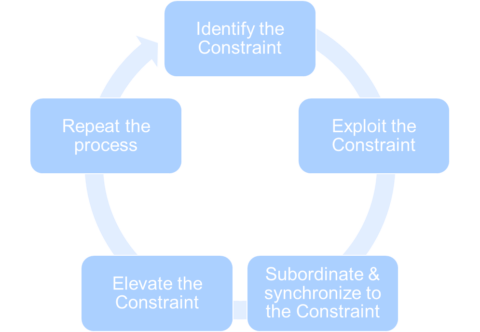

- Throughput optimization: Does the machine improve cycle times and reduce bottlenecks?

How Simulation Helps

inFACTS Studio enables companies to:

- Simulate different equipment configurations to compare cost and performance trade-offs.

- Test automation and manual workflows to determine the best balance.

- Optimize investment decisions by validating capacity and cost.

Expected Results

- Optimized equipment investments by selecting the best-fit solution.

- Improved production efficiency with validated system performance.

- Reduced investment risks by ensuring equipment aligns with operational needs.

With inFACTS Studio, businesses can make informed equipment selections that enhance performance while controlling costs.