Layout Planning – Optimizing Facility Efficiency

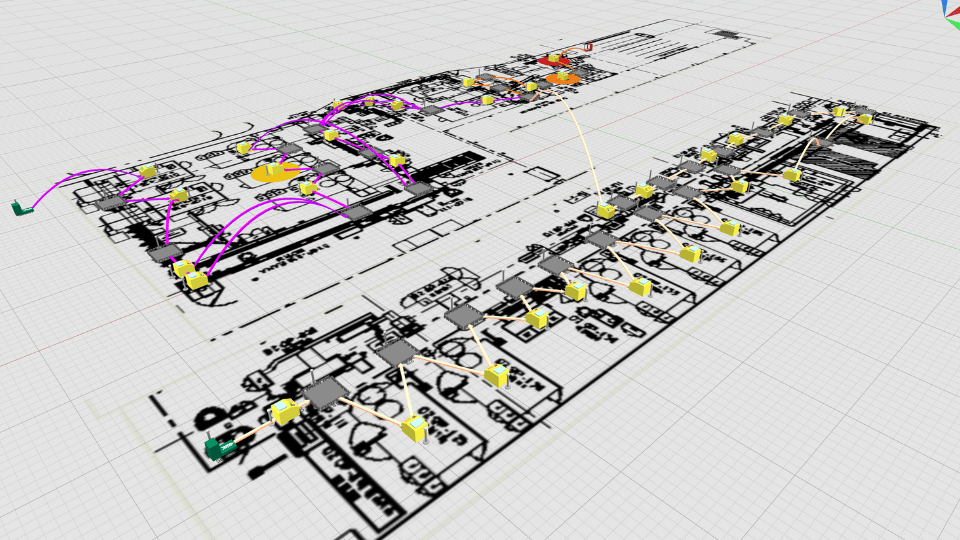

Factory layout design impacts material flow, congestion, and operational costs. Optimizing workstation placement, storage areas, and logistics pathways enhances efficiency, reduces travel time, and improves space utilization.

Challenges

- Material flow inefficiencies: How can layout design reduce unnecessary transport and waiting times?

- Space utilization: How should workstations, storage, and logistics areas be arranged for maximum efficiency?

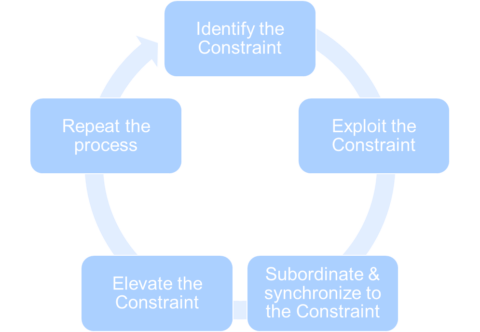

- Bottlenecks & congestion: How do layout choices affect movement and process flow?

- Operational costs: How does facility design impact energy consumption, labor efficiency, and equipment utilization?

How Simulation Helps

inFACTS Studio enables companies to:

- Compare multiple facility layouts in a virtual environment before finalizing designs.

- Analyze material flow efficiency to identify and eliminate bottlenecks.

- Optimize space utilization by testing workstation and storage placements.

- Assess the impact of different layouts on travel time, labor productivity, and operational costs.

Expected Results

- Reduced travel time and congestion with optimized layout design.

- Lower operational costs by improving space and resource efficiency.

- Data-driven facility planning ensures long-term adaptability and scalability.

With inFACTS Studio, businesses can design, test, and validate facility layouts before implementation, leading to smarter, more efficient production environments.

NOTE: Better support for layout and internal logistics is to be launched during 2025.