Pre-RFQ Simulation – Ensuring Feasibility Before Procurement

Before sending RFQs, companies need to validate production feasibility, assess process constraints, and compare supplier solutions. Ensuring realistic specifications can optimize procurement decisions and minimize investment risks.

Challenges

- Cost estimation uncertainty: How can production feasibility be verified before sending Request For Quotations (RFQs)?

- Process validation: Will the proposed manufacturing process meet production targets?

- Supplier comparison: How do different equipment or process choices impact performance and cost?

- Investment risk: How to ensure RFQs reflect realistic production constraints and opportunities?

How Simulation Helps

inFACTS Studio enables companies to:

- Run production scenarios to validate cost estimates and feasibility before RFQ submission.

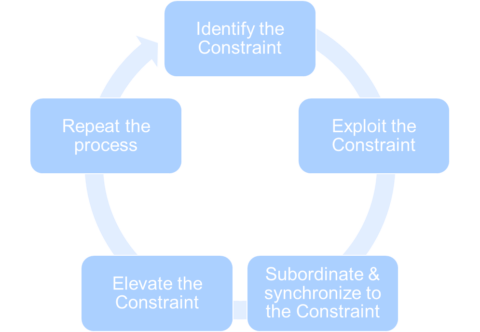

- Analyze process constraints to refine specifications and avoid incorrect assumptions.

- Compare potential suppliers by testing different equipment and process setups.

- Optimize procurement decisions with simulation-backed insights on cost-performance trade-offs.

Expected Results

- Stronger supplier negotiations with fact-based RFQ insights.

- Minimized procurement risks by ensuring production feasibility upfront.

With inFACTS Studio, businesses can ensure well-informed RFQs, improving supplier selection and overall cost efficiency.