Ramp-Up & Ramp-Down – Managing Production Scale Changes Efficiently

Scaling production up or down requires precise workforce and resource allocation while minimizing inefficiencies. Planning for supply chain adaptability and cost control ensures smooth transitions.

Challenges

- Balancing speed & stability: How quickly can production be scaled up or down without causing disruptions?

- Resource allocation: What is the optimal workforce and equipment distribution during scaling phases?

- Supply chain readiness: How do material availability and logistics adapt to production changes?

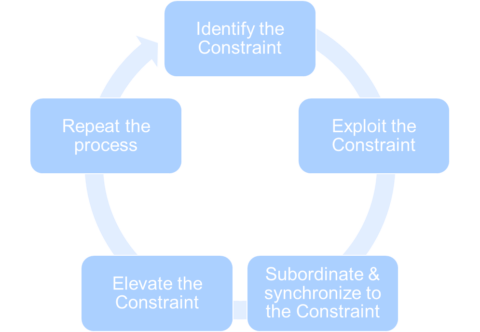

- Bottlenecks & inefficiencies: What constraints may arise when adjusting production volume?

- Cost control: How to minimize expenses associated with scaling operations up or down?

How Simulation Helps

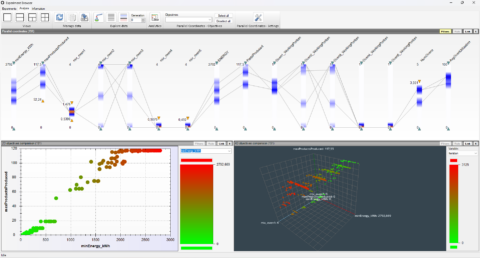

inFACTS Studio enables companies to:

- Test different ramp-up and ramp-down strategies in a virtual environment before execution.

- Analyze resource and workforce requirements to ensure smooth transitions.

- Identify bottlenecks and inefficiencies before they disrupt production.

- Optimize cost-effective scaling by evaluating different scenarios.

Expected Results

- Smoother production transitions with minimized disruptions.

- More efficient resource utilization by ensuring proper workforce and machine distribution.

- Lower scaling costs through optimized decision-making.

With inFACTS Studio, businesses can plan and execute production scale adjustments confidently, ensuring stability, efficiency, and cost-effectiveness.