Supply Chain Planning Tool – Preparing for Future Challenges

Long-term supply chain stability depends on optimizing facility locations, capacity scaling, and sustainability. Companies must proactively simulate global risks and evaluate production footprint strategies.

Challenges

- Long-term supply chain adaptability – How can companies design a supply chain that remains resilient in the face of geopolitical shifts, material shortages, and evolving market trends?

- Strategic production footprint – Where should future production and distribution facilities be located to optimize costs and minimize risks?

- Scaling for future demand – How to evaluate production capacity needs for the next 5–10 years based on projected demand growth and product mix changes?

- Sustainability & compliance – How can companies integrate sustainability goals and regulatory compliance into long-term supply chain planning?

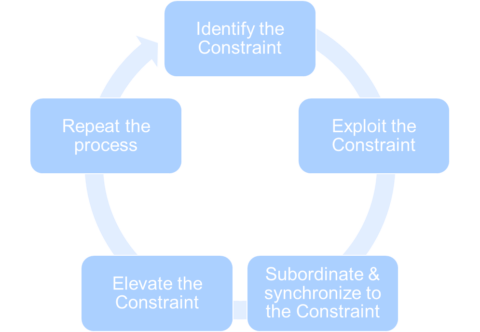

How Simulation Helps

- Scenario planning for future uncertainties – Simulate global supply chain risks, including trade restrictions, transportation disruptions, and raw material shortages.

- Facility and resource planning – Optimize factory and warehouse locations, considering costs, lead times, and regional policies.

- Capacity scaling strategies – Model how future demand changes impact production lines, workforce needs, and automation investments.

- Sustainable supply chain design – Evaluate carbon footprint, energy efficiency, and waste reduction strategies in logistics and production flows.

Expected Results

- Resilient supply chain design – Proactive risk mitigation through strategic scenario testing.

- Optimized global footprint – Informed decisions on where to invest in new facilities and infrastructure.

- Future-proofed production planning – Scalable operations that align with long-term business goals.

With inFACTS Studio and custom plugin solutions from Evoma, companies can proactively plan their supply chain strategy, ensuring sustainable growth and operational stability in an evolving business landscape.