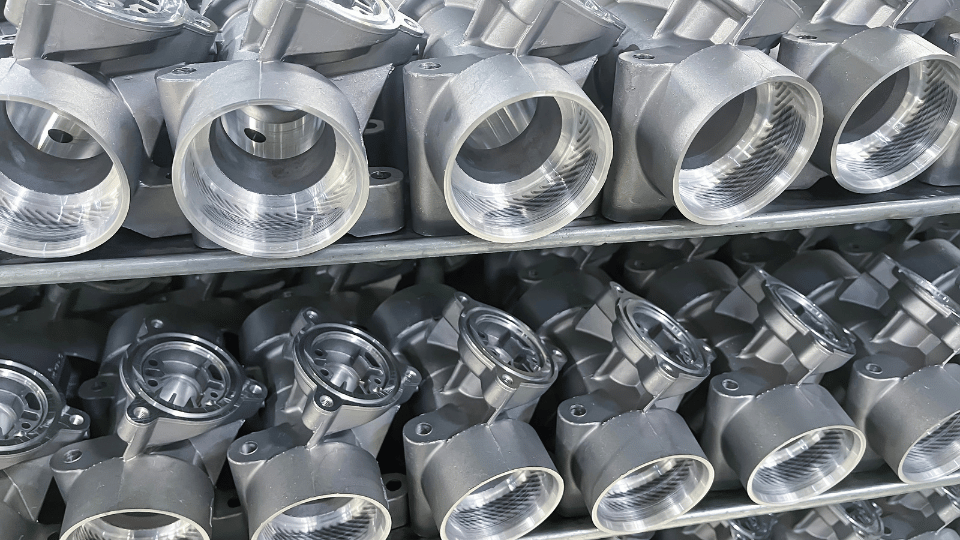

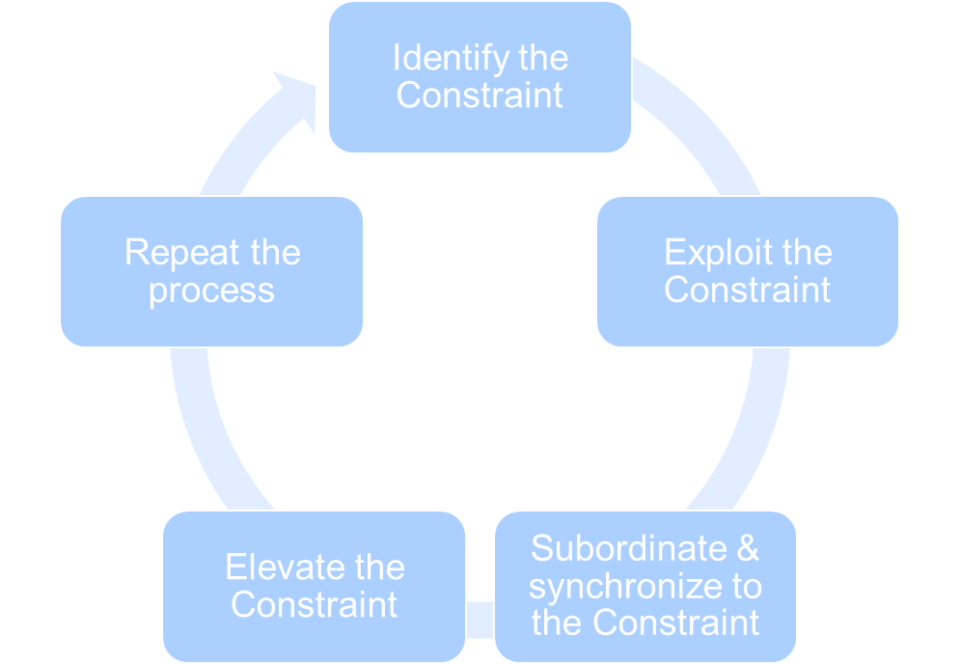

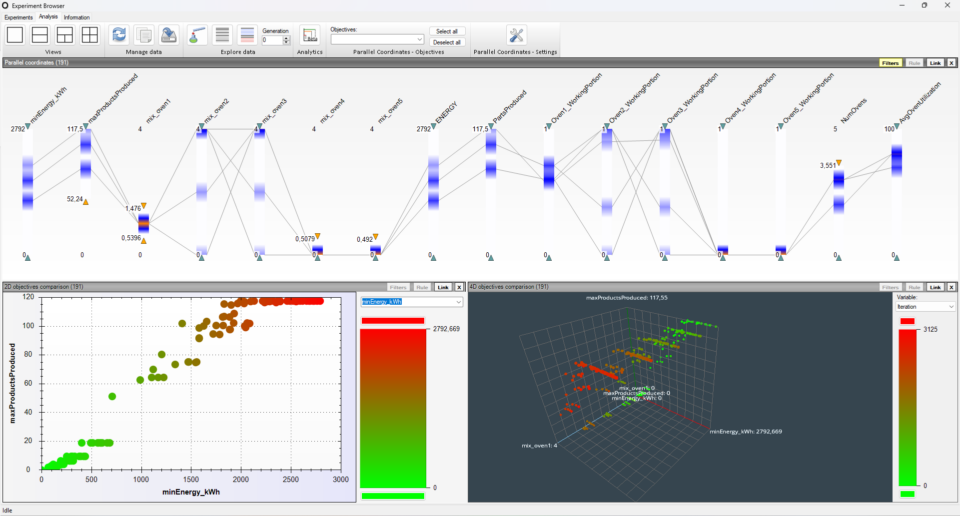

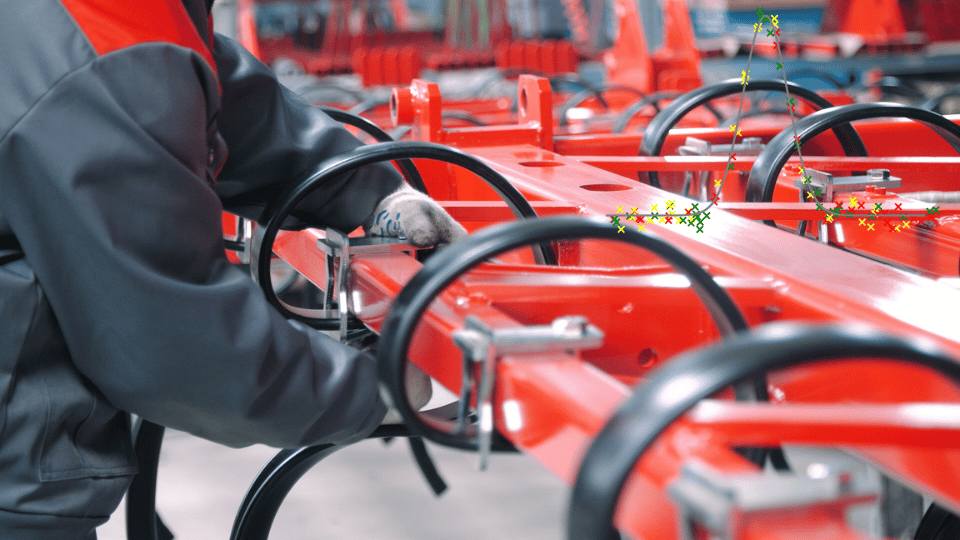

Aerospace, Automotive, Healthcare, Logistics, Manufacturing, Mining