Consulting Services

Evoma’s consulting services help companies analyze, optimize, and transform their operations through data-driven insights and simulation expertise.

Management Consulting

Strategic transformation, efficiency, and digital innovation guidance.

Production Flow Analysis

Improve flow using VSM, data, and simulation insights.

Decision Support in Projects

Validate investments through data-driven scenario modeling.

Simulation Consultancy

Support during peak workloads and specialized model development.

Management Consulting

We support organizations in shaping strategy, driving transformation, and leading change. By combining deep business insight with data-driven analysis, we help leadership teams identify challenges, uncover opportunities, and make confident, future-ready decisions.

Our expertise covers:

- Strategy Development & Business Transformation – Guiding organizations through strategic shifts and long-term growth planning.

- Operational Excellence & Change Management – Aligning people, processes, and systems to boost performance and adaptability.

- Digitalization & Innovation Enablement – Helping leaders drive innovation through smart use of digital technologies.

- Decision Support & Risk Mitigation – Strengthening strategic decisions with evidence-based insights and foresight.

Evoma ensures that complex business challenges are addressed with evidence-based strategies, minimizing risks and maximizing efficiency before changes are implemented. For deeper expertise, explore:

- Production Flow Analysis – Understanding, optimizing, and balancing production systems.

- Decision Support in Projects – Leveraging simulation-driven insights for major business decisions.

- Simulation Consultancy – Support during peak workloads and specialized model development.

Production Flow Analysis

Understanding and optimizing production flows is crucial for reducing inefficiencies, increasing productivity, and ensuring smooth operations. At Evoma, we combine traditional manufacturing expertise with cutting-edge simulation and data analytics to provide actionable insights for shop floor improvements.

-

- Bottlenecks & Imbalances – How can workstations and processes be balanced to improve flow efficiency?

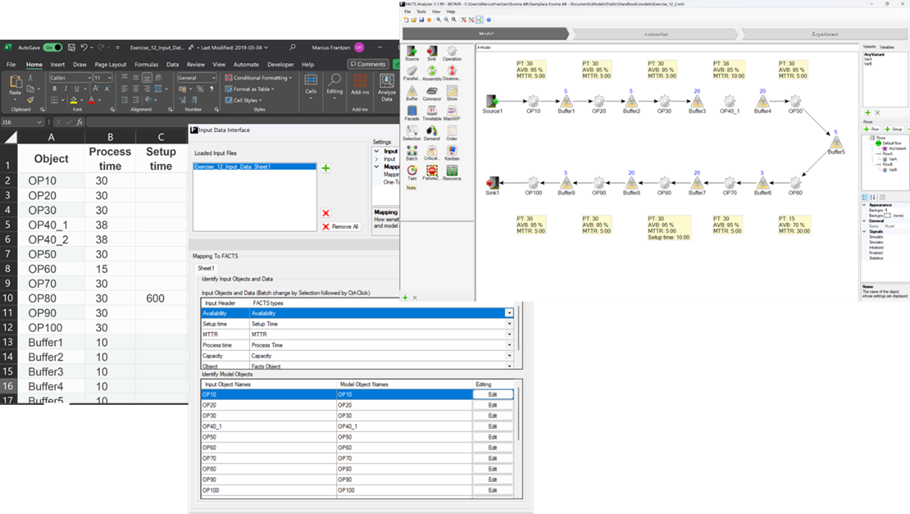

- Process Visibility – How can companies move from manual tracking (Excel, paper-based reports) to data-driven decision-making?

- Inventory & Material Flow – How much in-process stock and buffer capacity is necessary without affecting production stability?

- Scalability & Future Adaptability – How can production layouts and processes be designed for future flexibility?

-

- Value Stream Mapping (VSM) – We conduct hands-on workshops to map current production flows, identifywaste, and define target conditions for improved efficiency.

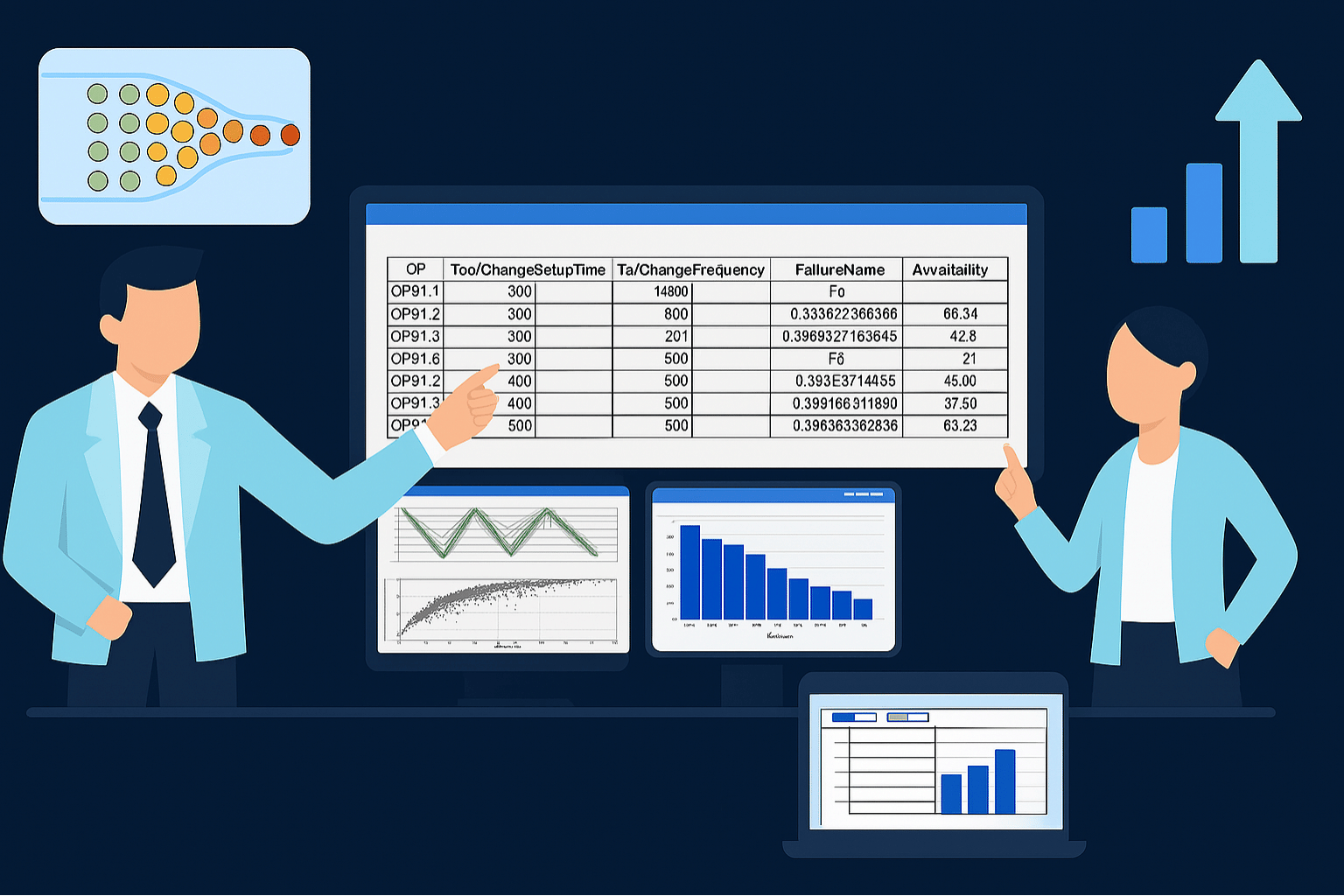

- Data-Driven Decision Support – Transition from Excel-based static calculations to dynamic, simulation-based planning tools.

- Production Simulations – Evaluate different what-if scenarios to optimize layout, automation, and work distribution.

- Lead-Time & Inventory Optimization – Analyze how much stock-in-process (WIP) and buffer capacity is needed to maintain high throughput.

- Workforce Utilization – Optimize operator movement and workload distribution to minimize non-value-added activities.

-

- Current State Mapping – Conduct on-site analysis with data collection, time studies, and process mapping.

- Future State Definition – Identify improvement opportunities and define target production flows.

- Simulation & Decision Support – Develop simulation models to validate improvements and assess long-term impact.

- Implementation & Continuous Improvement – Support execution of process changes and provide ongoing decision support tools.

-

- Optimized Production Flow – Fewer bottlenecks and higher efficiency.

- Reduced WIP & Lead Times – Lower inventory costs while maintaining stable production.

- Improved Workforce & Resource Allocation – Ensuring the right resources are in the right place at the right time.

- Future-Proof Operations – Scalable production processes designed for long-term adaptability.

Through a combination of traditional industrial engineering methods (VSM) and advanced simulation-based decision support, we help companies transition toward data-driven production flow optimization—improving both short-term operations and long-term strategic planning.

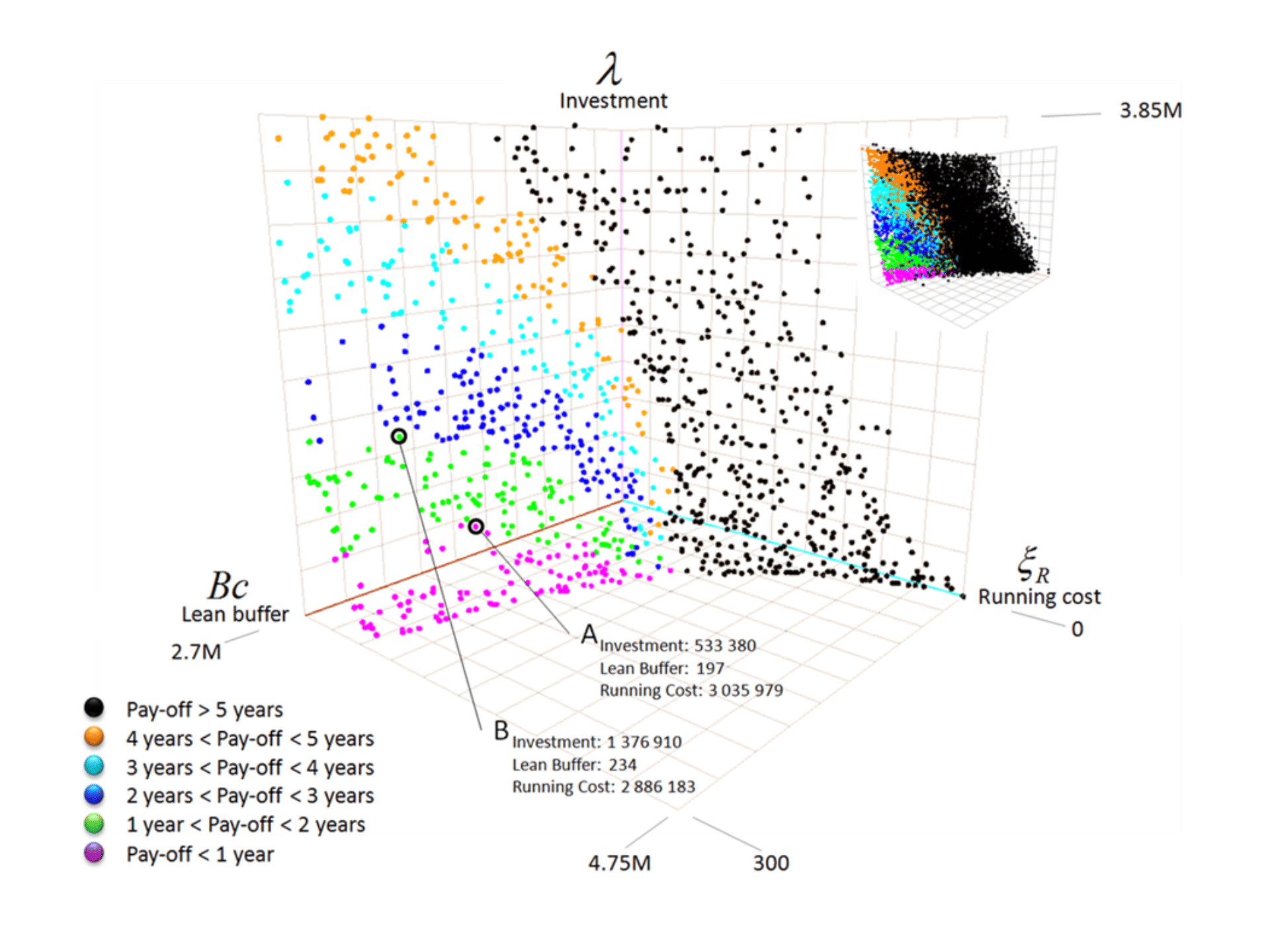

Decision Support in Projects

Major investments and process changes require careful planning, risk assessment, and validation before implementation. Evoma provides simulation-based decision support to ensure that business-critical choices are based on data and predictive insights, rather than assumptions.

How We Help

- Investment Decision Support – Assess the impact of new equipment, factory expansions, and automation projects before committing capital.

- Supply Chain & Logistics Strategy – Evaluate sourcing, distribution, and resilience strategies to minimize risk and optimize efficiency.

- Production System Design – Simulate different layouts, capacity planning, and process optimizations to find the most effective setup.

- Risk & Uncertainty Analysis – Use what-if scenario testing to anticipate disruptions, evaluate contingencies, and improve decision-making.

Why Simulation-Based Decision Support

Using discrete event simulation, optimization, and AI-driven analytics, Evoma helps companies make informed, data-driven decisions with confidence. By testing multiple scenarios before implementation, organizations can ensure that investments deliver maximum value with minimal risk.

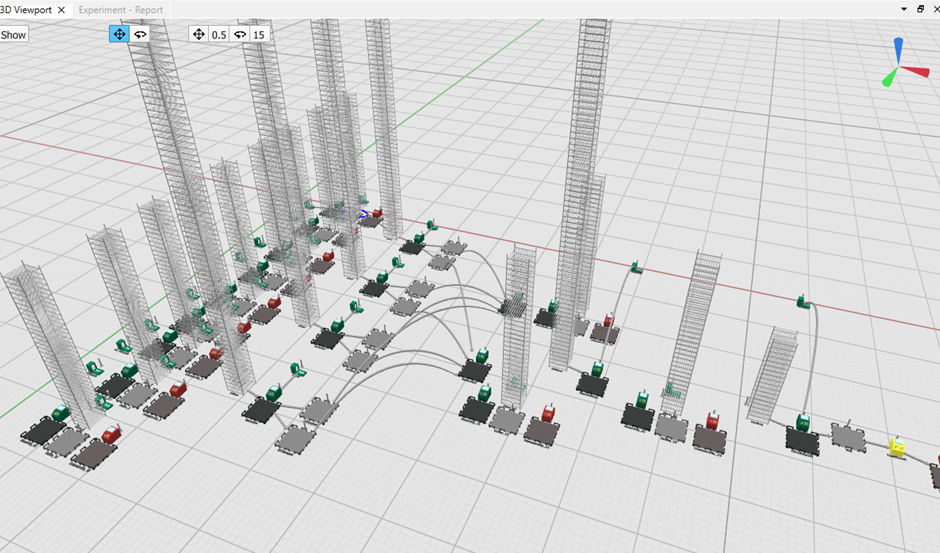

Simulation Consultancy

Evoma provides specialized simulation expertise to help companies integrate, expand, and optimize their use of discrete event simulation (DES). Whether you need temporary support during peak workloads, custom adaptations, or strategic guidance for integrating simulation into decision-making, we offer tailored solutions.

How We Help

- Flexible Simulation Support – Assist companies with high workloads or specialized projects.

- Custom Model Development – Build industry-specific simulations for production, supply chain, and logistics.

- Advanced Adaptations & Expertise – Provide in-depth knowledge in optimization, AI, and complex system modeling.

- Simulation Integration & Digital Transformation – Guide organizations in embedding simulation as a standard tool for strategic decision-making.

- Training & Ongoing Support – Equip teams with the skills to develop and maintain their own simulation models.

With a highly skilled team and years of experience in simulation-driven decision support, Evoma helps businesses reduce risk, enhance decision-making, and maximize the value of simulation technology.

Explore Real Business Cases & Use Cases

See how Evoma’s solutions can help companies improve manufacturing efficiency, supply chain resilience, and investment decisions.

Business cases

Use cases

Interested in our Consulting Services?

Contact us to discuss your needs and how Evoma can help your business.