Automatic Model Generation

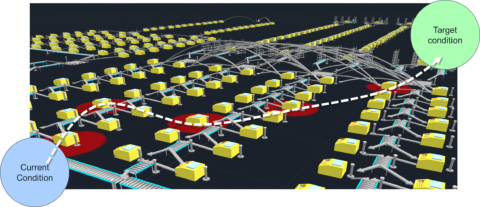

An automotive manufacturer faced inefficiencies in early project phases due to the manual creation of production simulation models. Without fast simulation capabilities, decision-making on alternative Bill-of-Process (BoP) flows was delayed, and production technicians struggled to analyze performance efficiently.

Challenge

An automotive manufacturer faced long lead times in early project phases due to the manual setup of production simulation models. The lack of fast simulation capabilities resulted in:

- Delayed decision-making in alternative Bill-of-Process (BoP) production flows.

- Limited ability for technicians to analyze production performance quickly.

- High effort required to create simulation models manually.

Solution

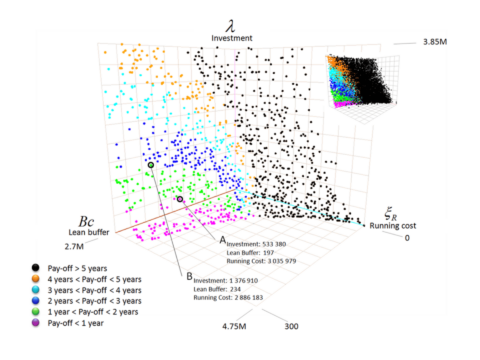

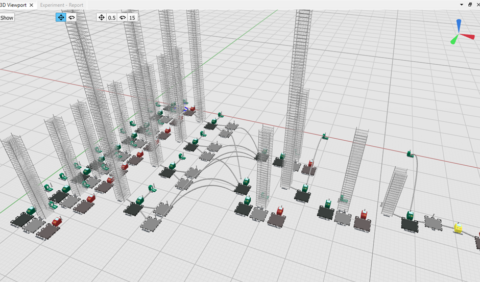

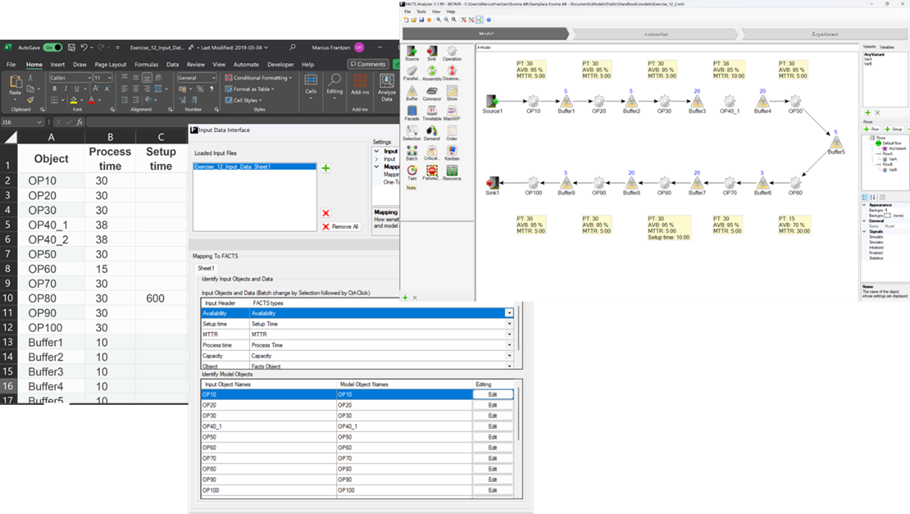

Evoma AB developed a software tool integrating automatic model generation within FACTS Analyzer*, which made the company to enable:

- Faster simulation model creation for early-stage analysis.

- Automated input processing to reduce time to input data.

- Production technicians to perform fast evaluations without expert simulation knowledge.

Results

- Significantly reduced model generation time, accelerating project timelines.

- Empowered production engineers to make quicker, informed decisions.

- Saved time and resources, improving operational efficiency.

Conclusion

By leveraging FACTS Analyzer’s automated model generation capabilities, the company streamlined early project planning, enhanced decision support, and reduced manual workload when testing early automotive production concepts.

*FACTS Analyzer was the previous generation of inFACTS Studio, built on a 2D environment.