The Company Bottleneck – Identifying & Removing Constraints

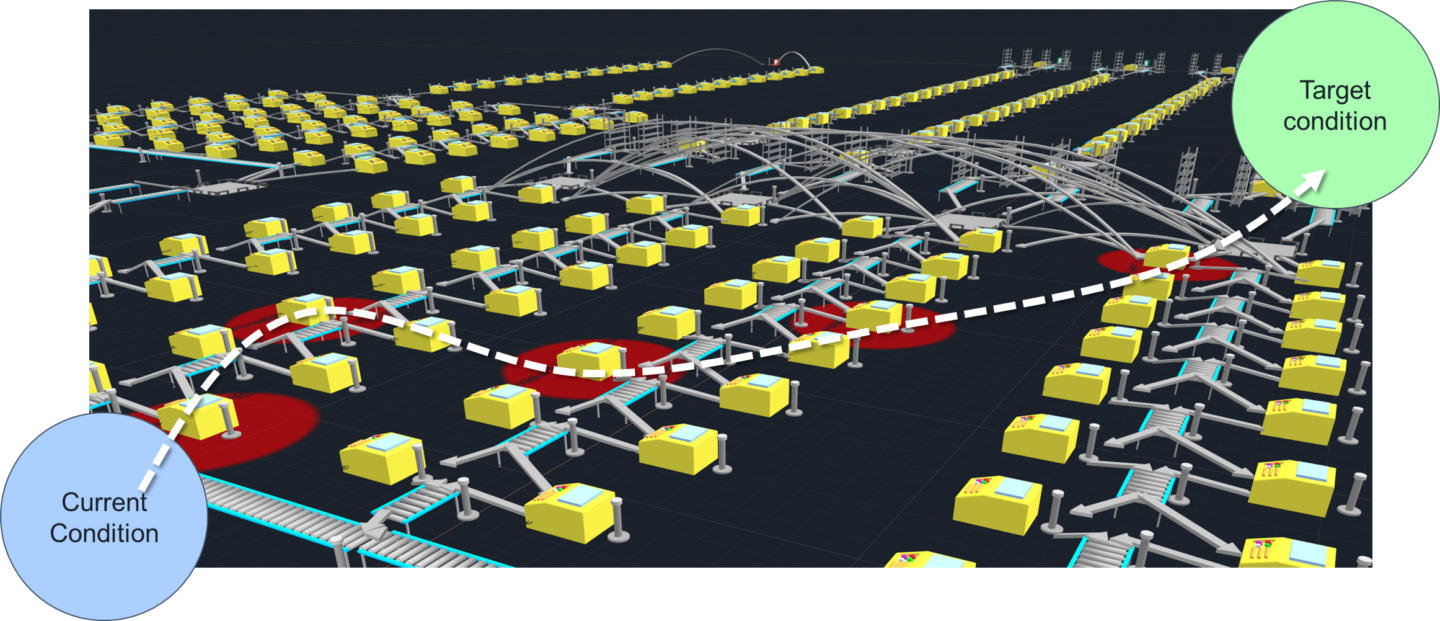

A company with a complex, multi-step production process struggled with bottlenecks, inefficient trial-and-error improvements, and limited visibility into key constraints like cycle times and downtime. These issues restricted throughput and hindered overall performance improvements.

Challenge

A company struggling with 50+ production steps faced:

- Bottlenecks in production flow, leading to inefficiencies.

- Trial-and-error approaches (Kata) without real improvements.

- Limited visibility into constraints, such as cycle times, availability, downtime, and setup times.

Solution

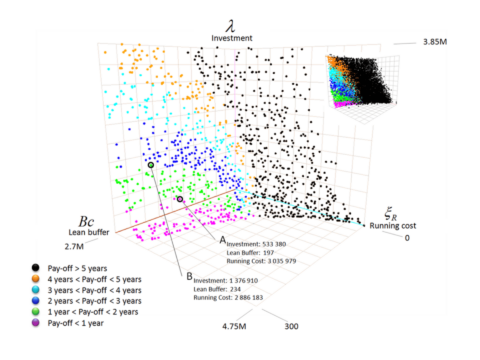

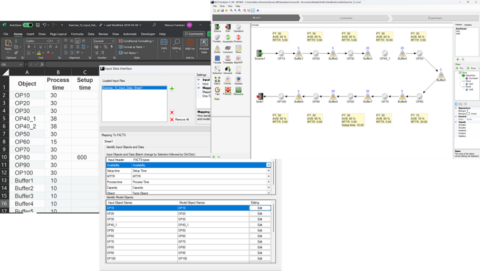

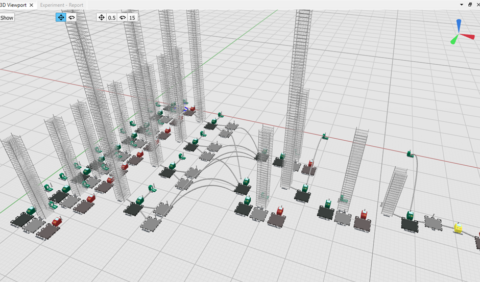

Using Simulation-Based Constraint Removal (SCORE) in FACTS Analyzer Professional*, the company:

- Identified 7 key improvements that significantly increased throughput.

- Used optimization tools to pinpoint exact constraints impacting performance.

- Replaced manual trial-and-error with data-driven optimization strategies.

Results

- Identified the necessary steps to increase throughput by 50%.

- Precise constraint identification, reducing inefficiencies.

- A structured path toward production improvement, rather than guesswork.

Conclusion

With SCORE optimization in inFACTS Studio, the company eliminated production constraints, increased throughput, and transitioned to a more structured, data-driven improvement process.

*FACTS Analyzer was the previous generation of inFACTS Studio, built on a 2D environment.

NOTE: current SCORE functionality to automate the construction of optimization problems are soon to be ported and integrated into the inFACTS Studio.